All Your condition monitoring assessments in one place.

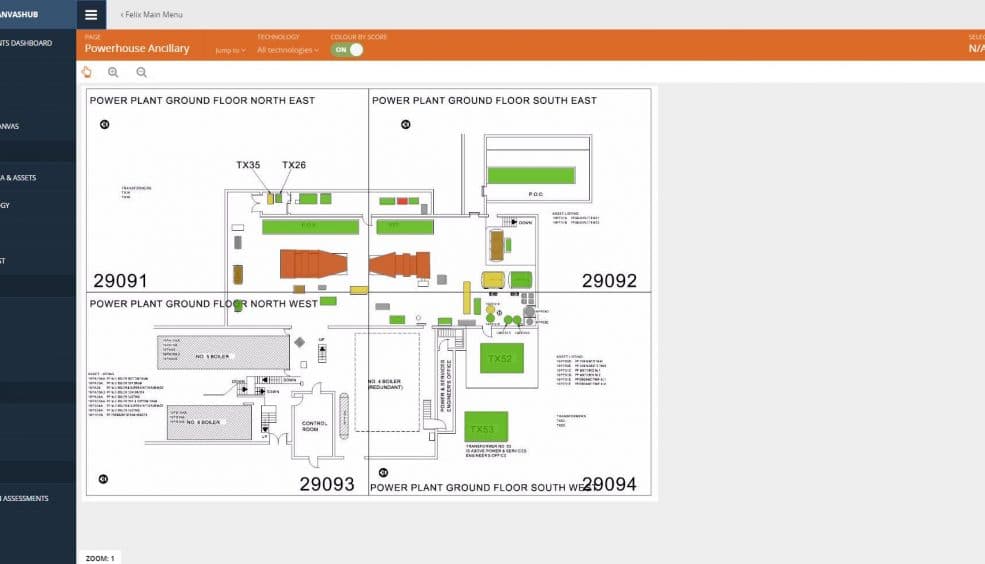

“As a technical decision maker I don’t always know everything there is to know, and everything that has been learned about the past present and future health of my assets, and hence make suboptimal decisions often based on rapid return to service, rather than failure mode elimination.”

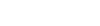

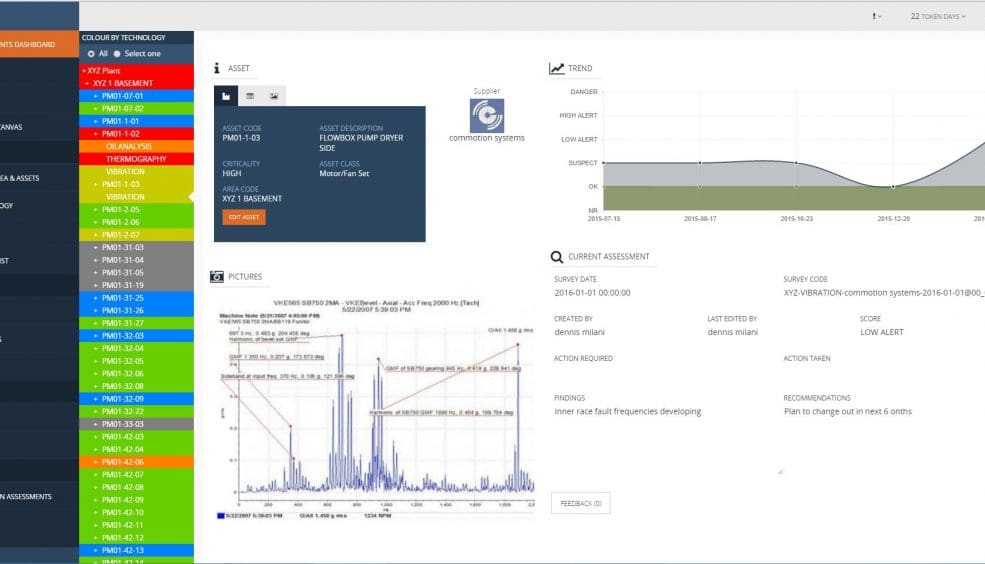

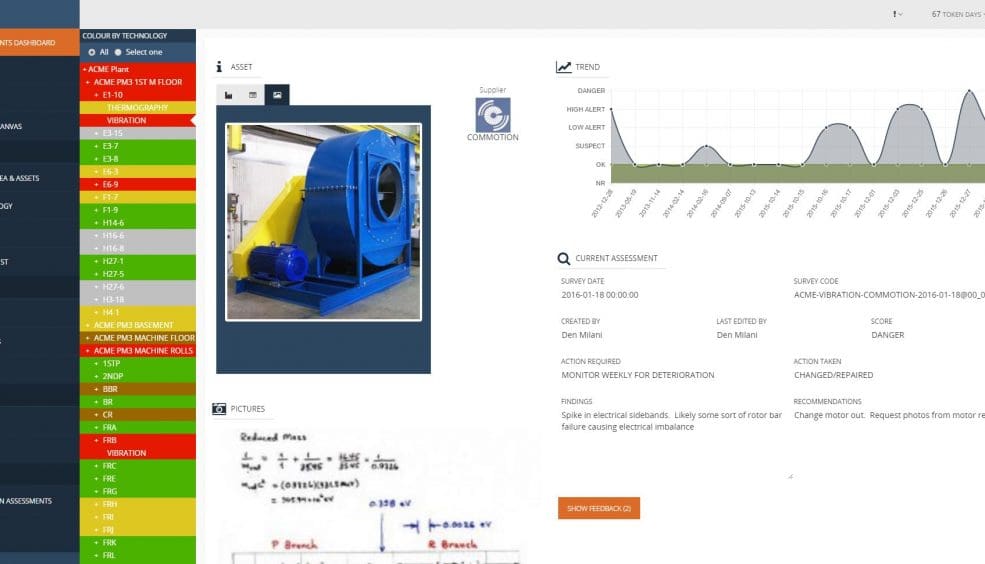

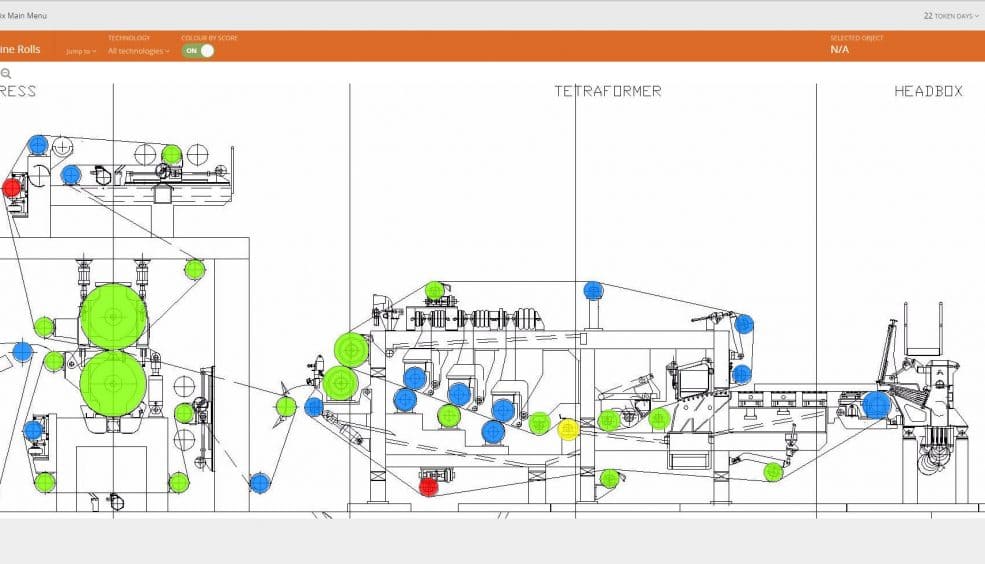

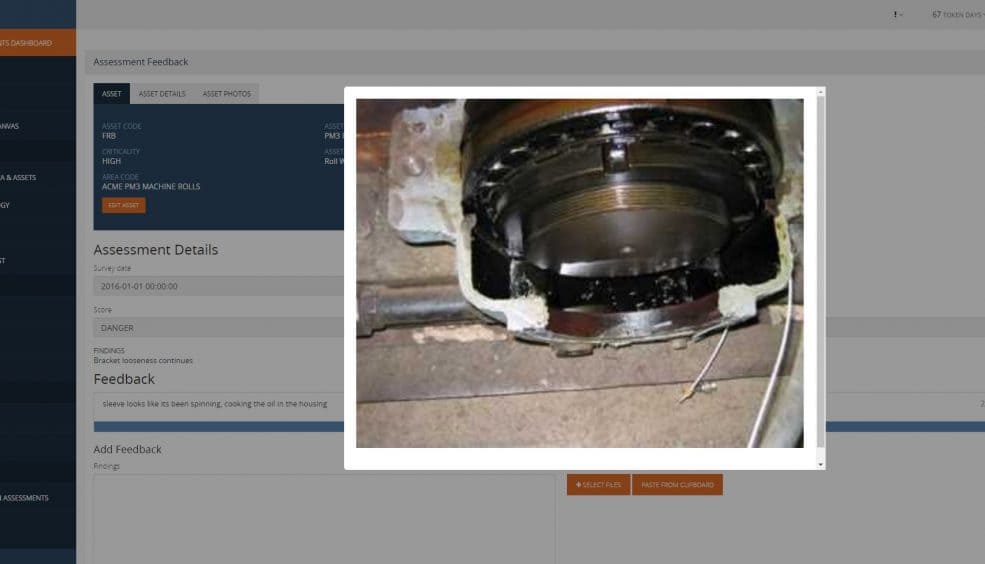

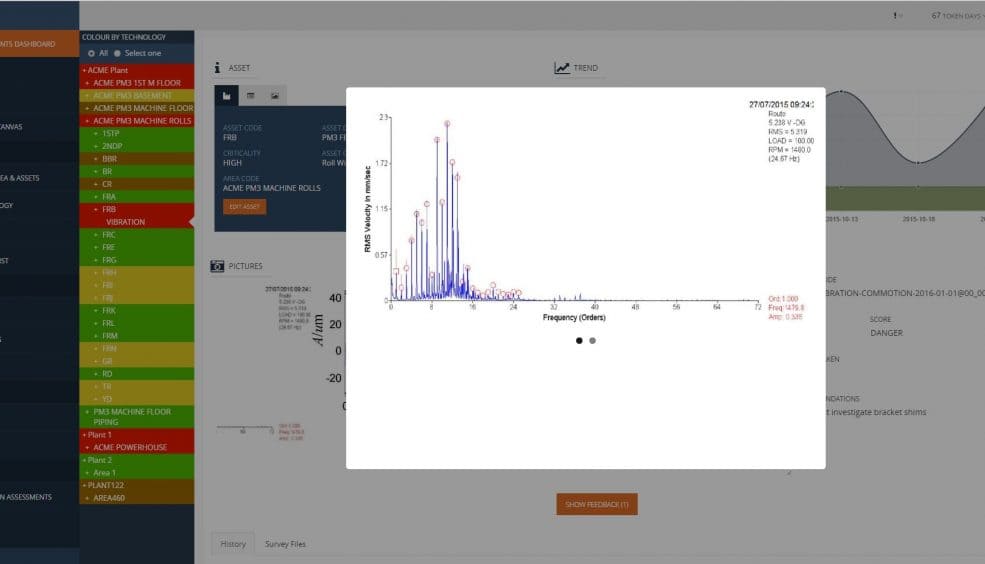

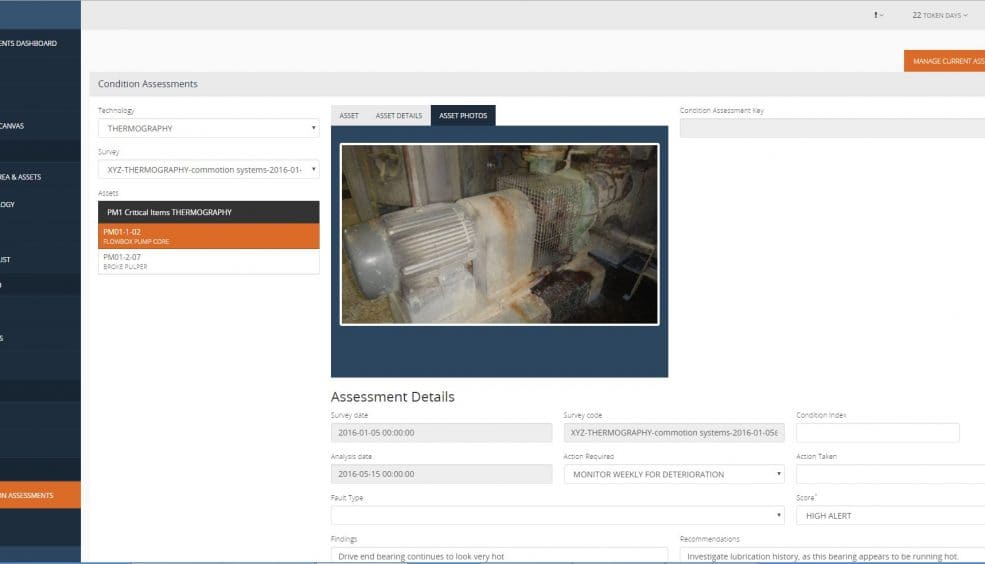

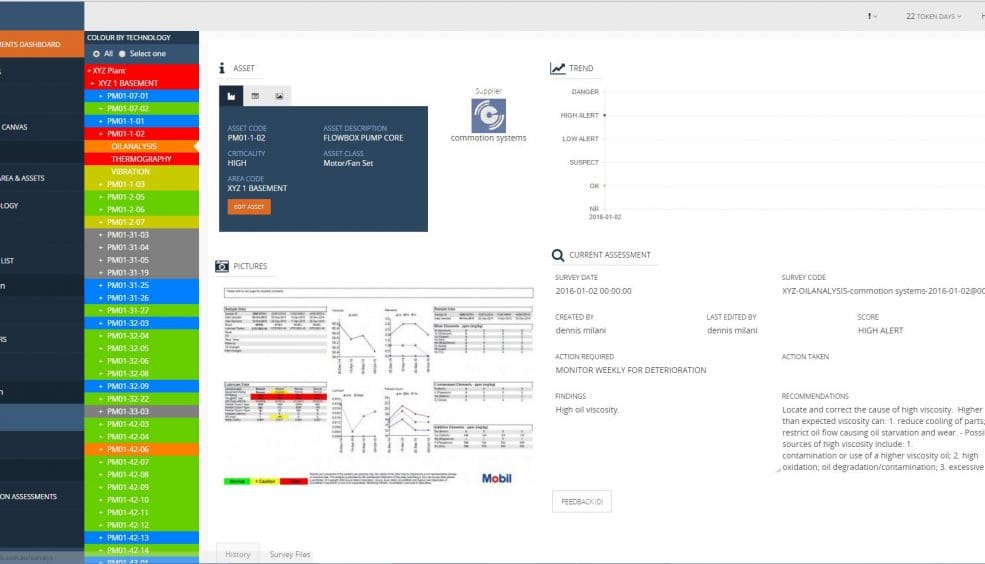

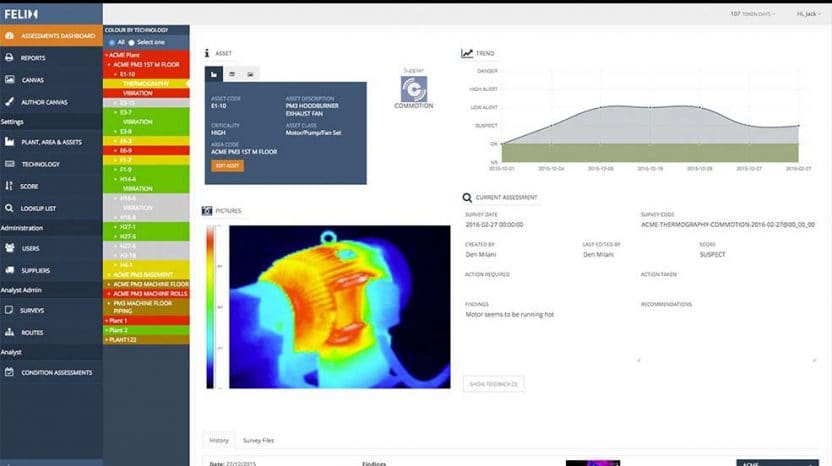

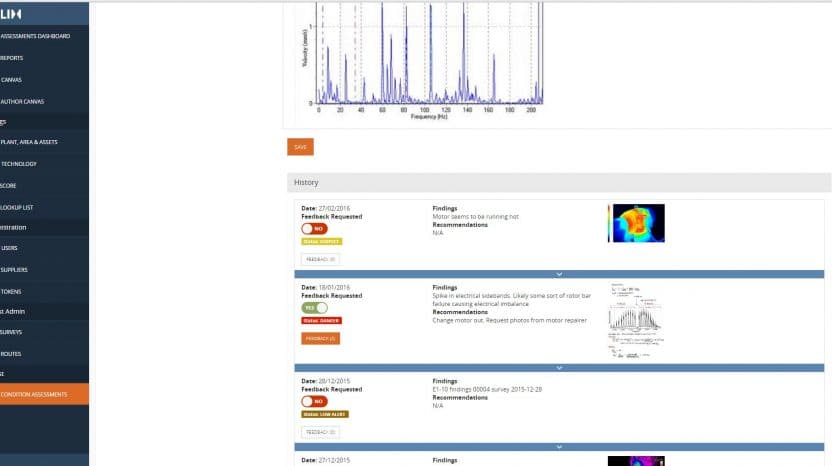

In Felix all condition assessments are recorded in one place, and require the outcome of each assessment to be recorded as concrete findings and recommendations. All analysis reporting is normalized into a common condition health status. Importantly Felix allows analysts to have at their fingertips all previous assessments across all technologies, plus any previous feedback from recommendations.

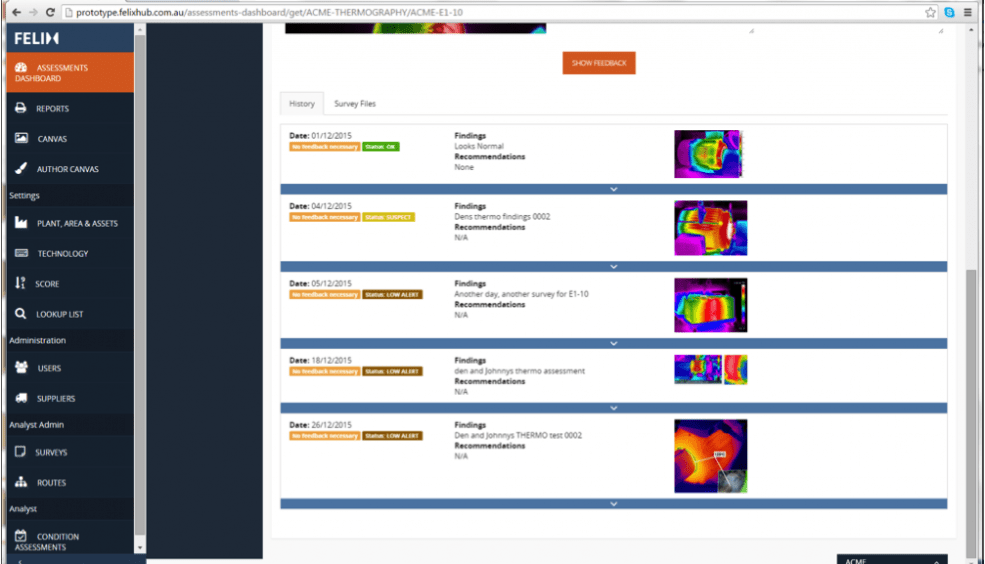

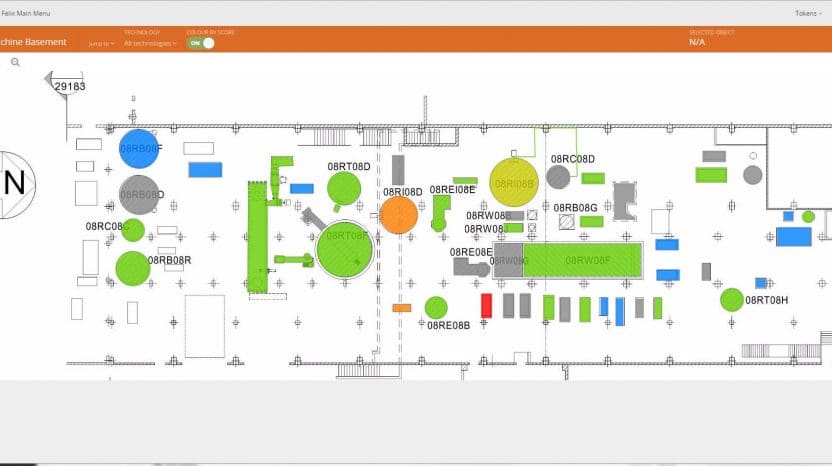

By recording finding and recommendations across all monitoring technologies and asset classes in a consistent manner a rich picture of asset health, and underlying failure mechanisms develops allowing better quality assessments, learning from prior findings, and visibility into all that is known about an asset’s health.

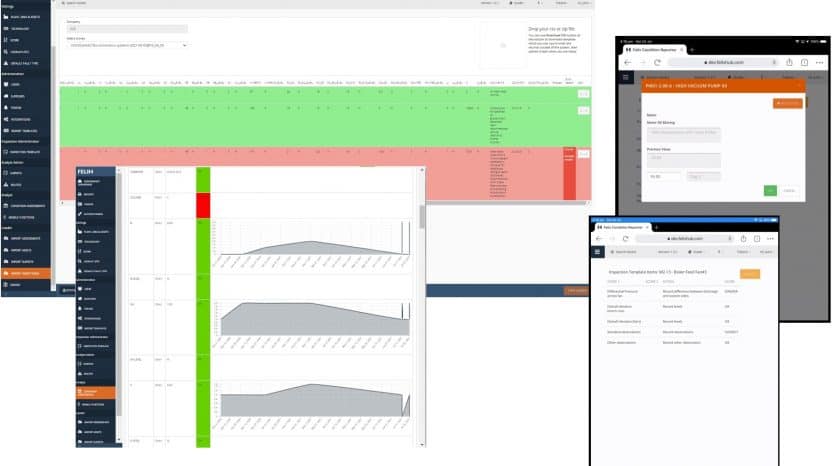

Felix allows inspection templates, and inspection routes to be created such that inspections can be conducted on any mobile device, or imported from external sources. Inspections from mobile devices automatically record GPS co-ordinates of where the inspection is conducted, and photos can be attached to any inspection.

Centralized, standardized, consolidated asset health status and history will provide an enabler for continuous improvement of your condition monitoring program outcomes.